News

RAICo Academic Showcase presents the next generation of robotics and AI for nuclear decommissioning

28 Jan 2026

For many, the big January tech event is CES in Las Vegas. Those working in nuclear decommissioning might disagree.

They chose to spend the 22nd of January in Cumbria, at the RAICo Academic Showcase, to learn about various academic projects on robotics and AI for decommissioning challenges.

Mel Willis, Robotics Research Lead at Sellafield Ltd, summed up the day in her keynote as “showcasing projects at the forefront of innovation in aerial, ground and underwater robots and AI”. She urged attendees “to engage with the brains in the room, and discuss your potential use cases, so that today’s cutting edge becomes business as usual on nuclear sites.”

Walking the floor of RAICo1 – RAICo’s main facility, where the event was hosted – gave attendees insight into eleven academic projects, some recently started, some at higher technology readiness levels and eyeing real-world deployment.

Let’s take a look at what they saw.

An immersive VR inspection robot

Attendees entering RAICo1 were met first with a robot that looks like a small go-kart. This wheeled robot – a project led by the University of Strathclyde – integrates cameras and purpose-built ultrasonic sensors, so that remote operators can ‘see what the robot sees’ via a VR headset. That creates an immersive experience that lets them get up close and personal with hazardous environments – with neat features such as overlaying historical data onto the video feed – all from a safe distance.

Seeing when the lights go out

Cameras mounted on robots give visual information when the lighting is good. But many robots on nuclear sites need to navigate pitch black abandoned buildings. So, the University of Manchester is developing a tool to turn an infrared camera feed from a robot into a clearer image, using machine learning to clear up noise. That can then feed back to the robot to help it navigate in the dark.

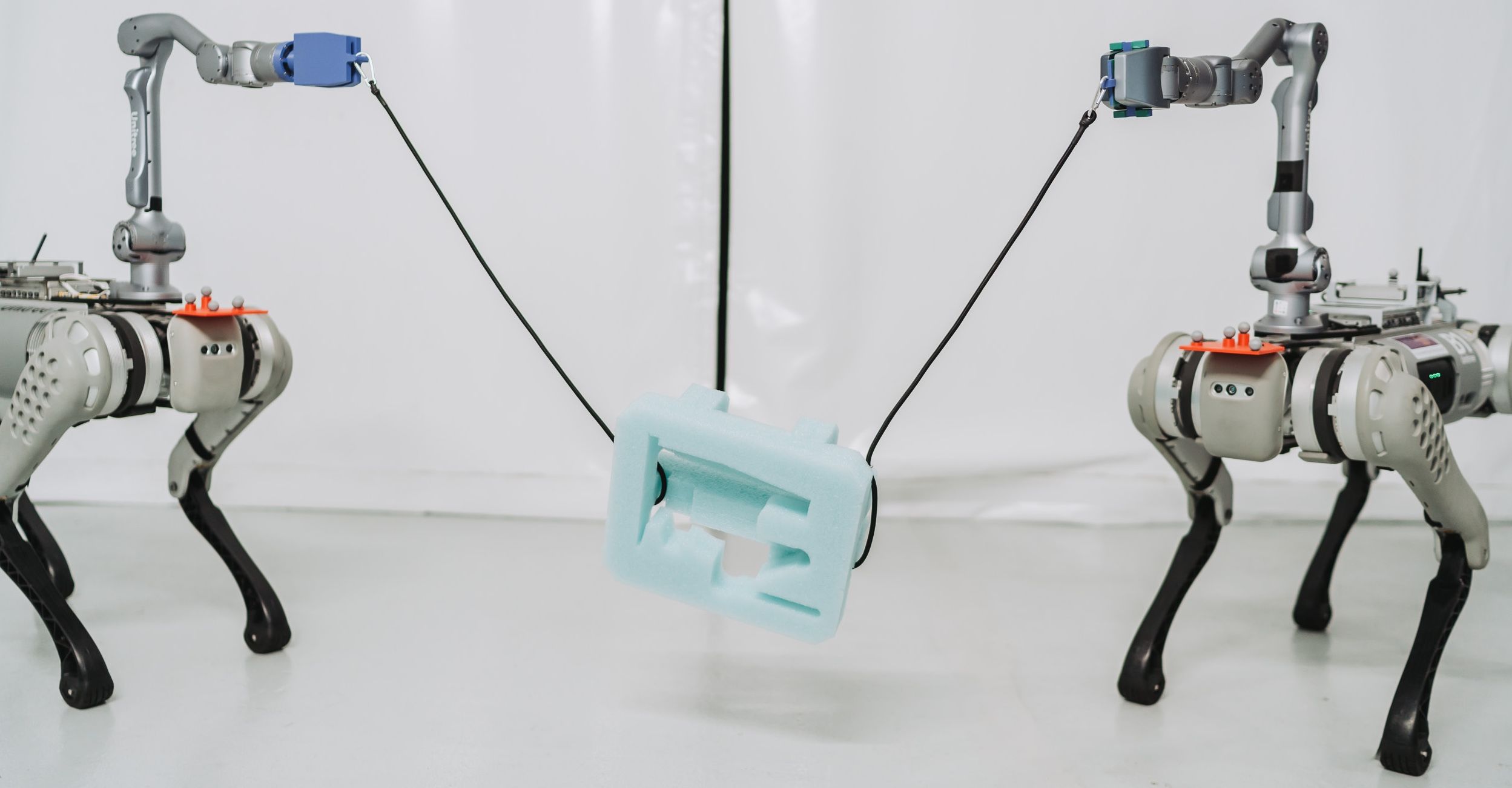

Collaborative quadrupeds

Next, we came to a perennial decommissioning favourite – robot quadrupeds. This University of Manchester project explored how multiple quadrupeds could work together to move bulky material on a nuclear site.

The system lets users set an instruction, such as drawing a path for the bulky item to be transported along. The quadrupeds then ‘talk’ to each other to work out how to move their legs and manipulators to support the object’s path – imagine two humans moving a table up a flight of stairs, constantly readjusting their position and grip. This is possible thanks to a complex mix of mathematical models for robot control and spatial awareness.

A slithering, serpentine servant

Not all land robots move on wheels or legs. The University of Nottingham’s snake robot is designed to slide through pipes and crawlspaces. It is mounted with a controllable sensor head – not dissimilar to that of a real snake – which can look around and collect video and data in all directions.

This innovation was noted by Luke Ankers at AWE Nuclear Security Technologies, who cited a potential use case of sending the snake to inspect an oily crawl space located under a large X-ray system.

Plumbing the depths

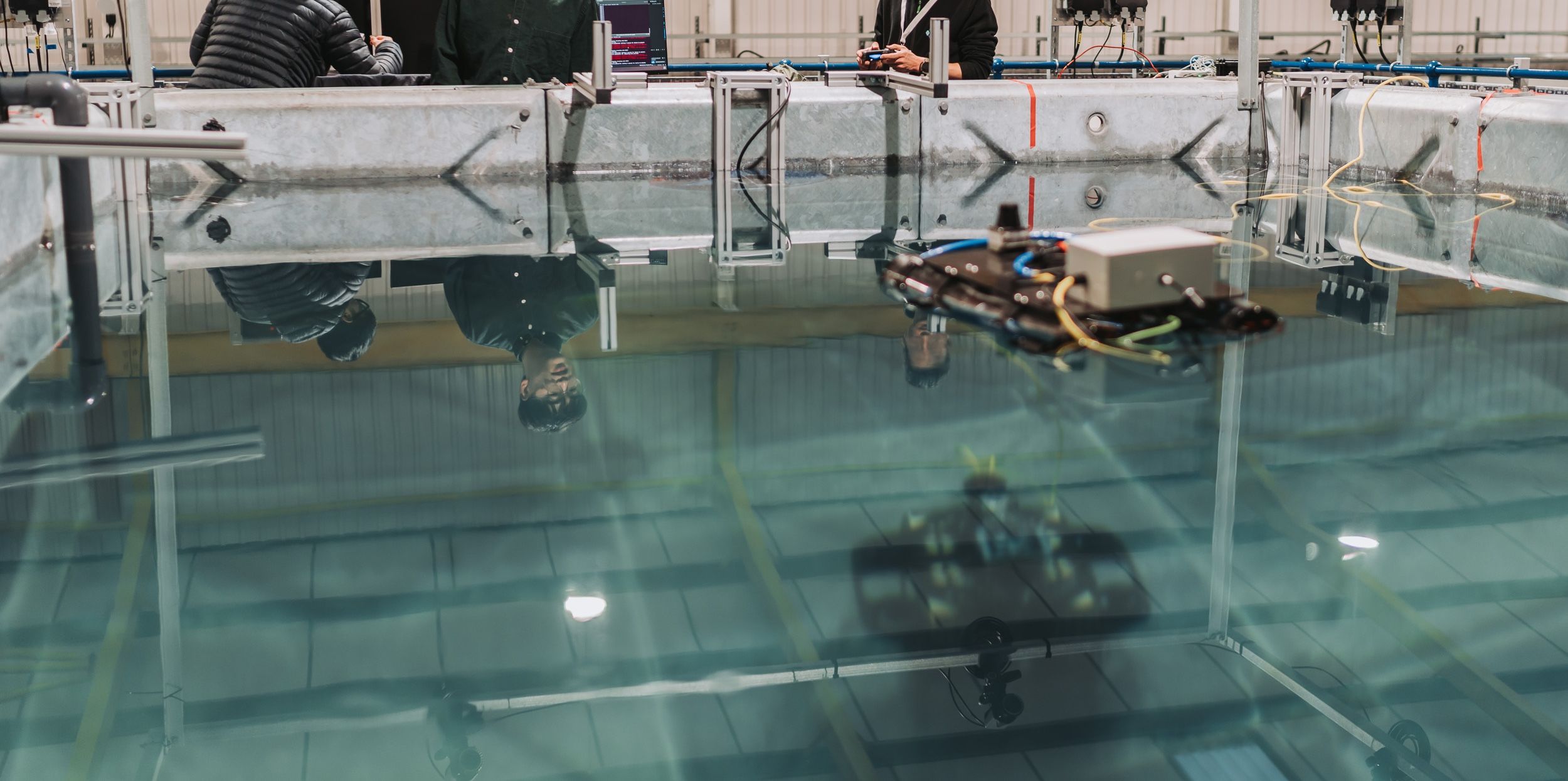

Some of the biggest challenges on sites like Sellafield are underwater fuel ponds, which are dark, cluttered and hard to navigate. So climbing a flight of stairs to RAICo’s water tank, we found two projects to address this.

The first, by The University of Manchester, brought together a team of surface and underwater vehicles. The surface vehicle helps its submerged partner with positioning and communication – mitigating the challenges of underwater vehicles sending data signals through different mediums and when visibility is reduced.

The second, from the University of Glasgow, uses AI for rapid 3D mapping of underwater environments, turning a camera feed from the underwater vehicle into a 3D map in seconds.

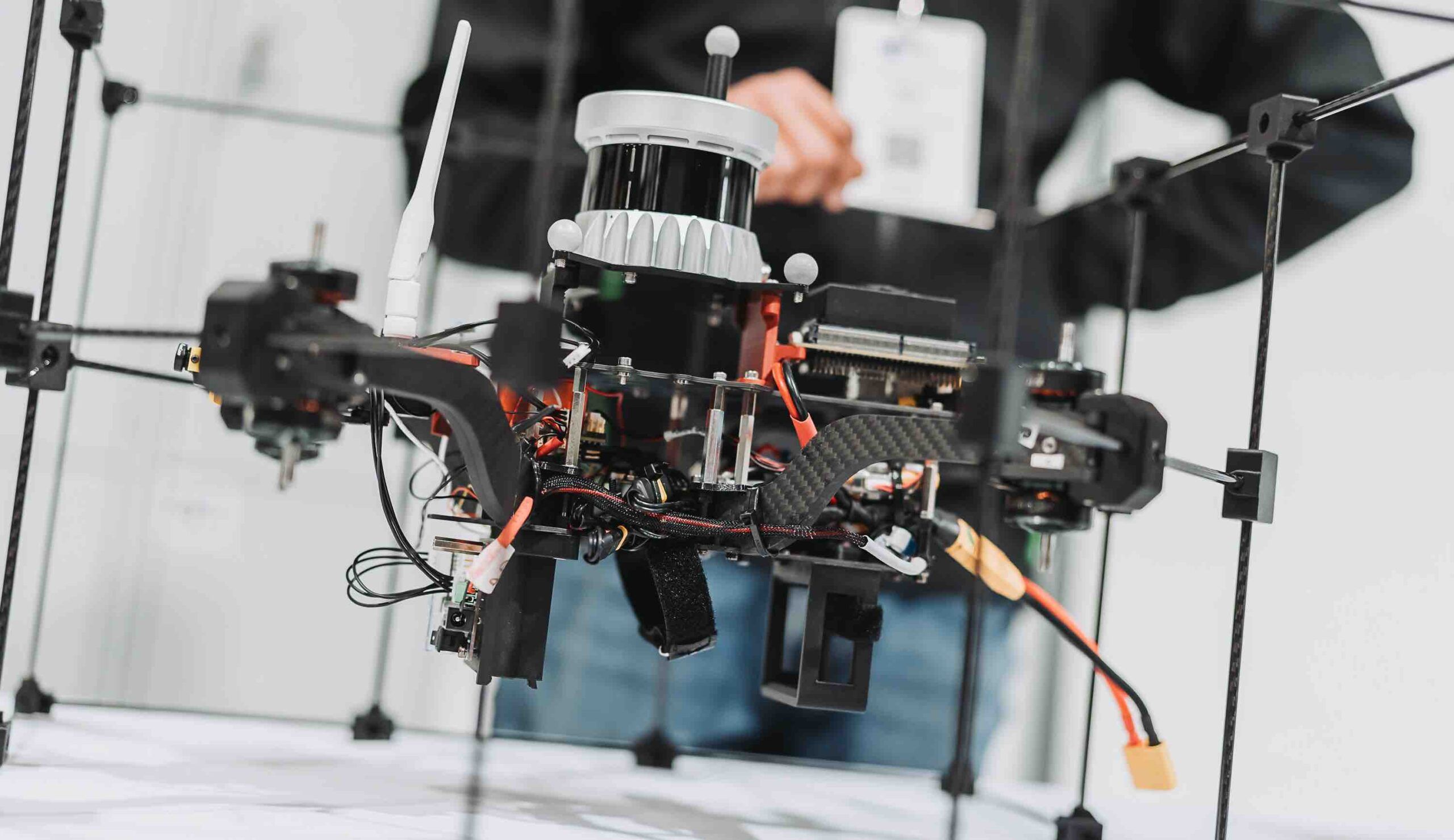

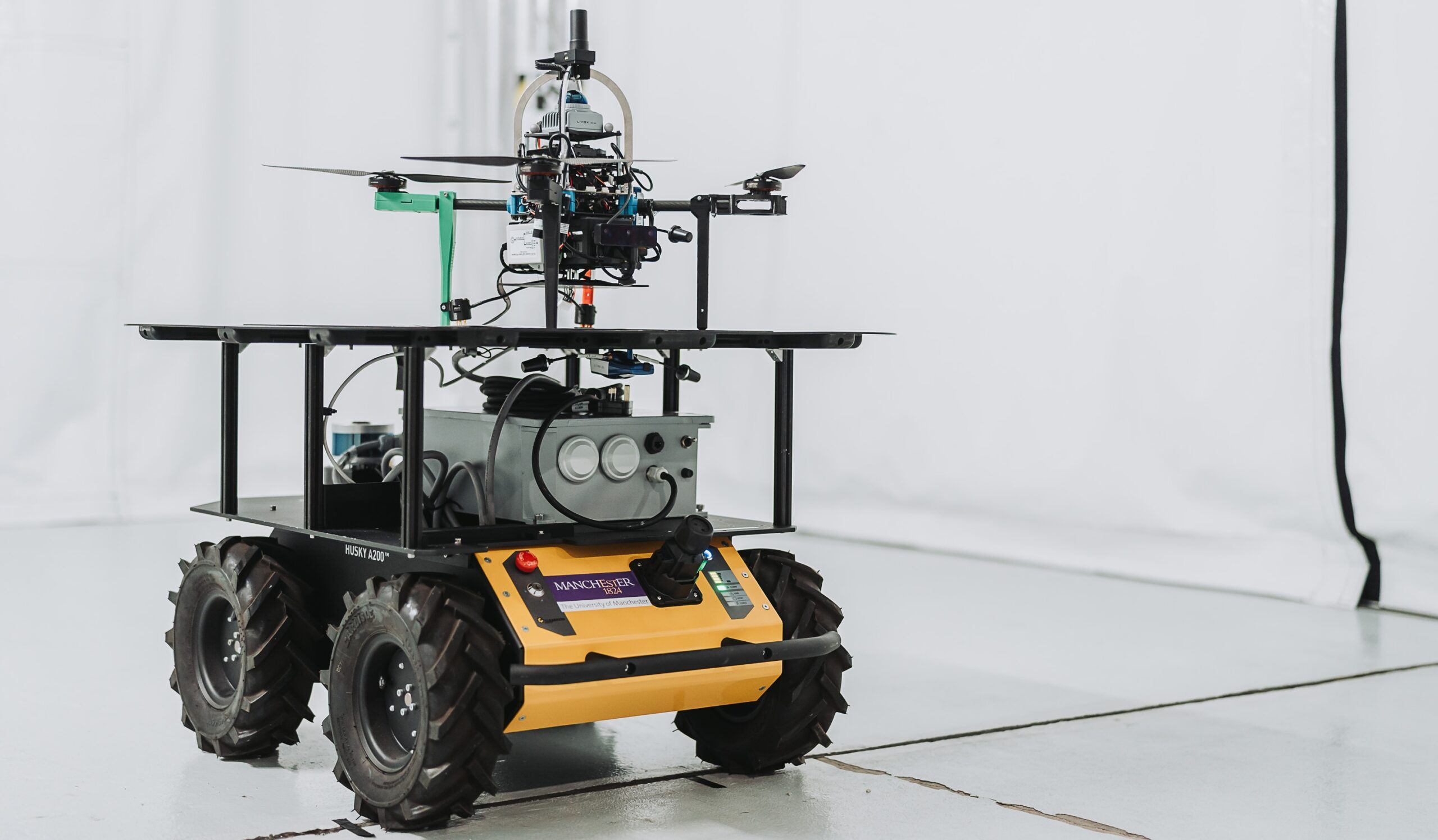

Longer lasting drones

Next, we look to the air. Drones are proving transformational for high up inspection. However, they are severely limited because their batteries don’t last long in flight. Two University of Manchester projects are trying to address this.

One has developed a system that allows drones to attach themselves to infrastructure, allowing them to power down their energy-hungry propellers while making their measurements, and so vastly extend inspection time.

The other is exploring using a ground charging vehicle. The small, remotely controlled platform can rove around a site and launch the drone for inspection as needed. When its battery gets low, the drone locates the platform using a shared model, and lands on its charging pad – where it can be powered up while it travels to its next mission.

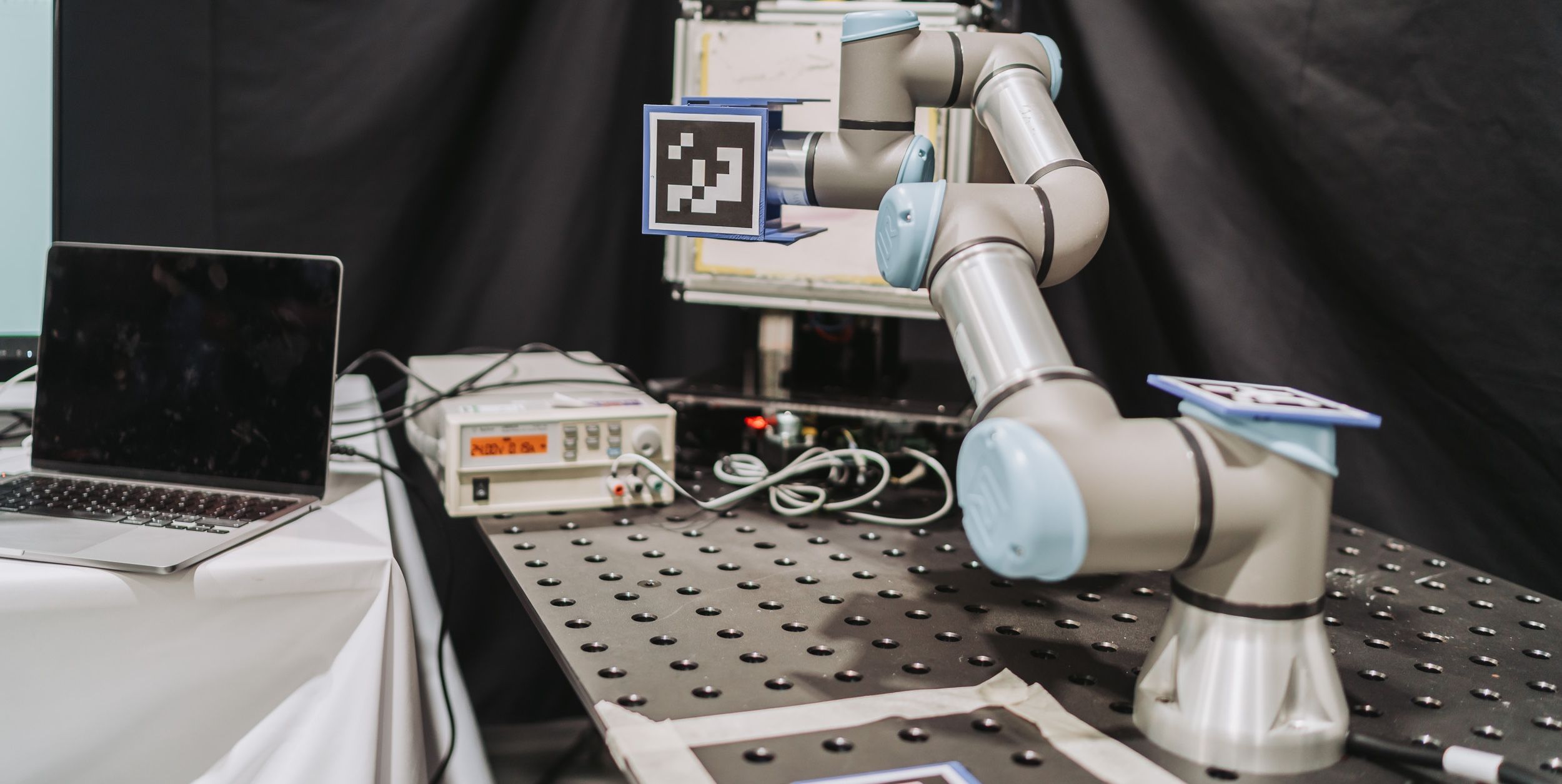

Smarter robot arms

Not all robots move around. Some are fixed robot arms used for things like cutting and polishing. Three University of Manchester projects in this field were presented.

One is a model to control robot arms to efficiently direct cutting lasers for the size reduction of solid nuclear waste. In the showcase demonstration, operators uploaded a cutting path for the laser to follow. But the long-term goal is an automated system that receives high-level goals (‘cut this skip so it fits into a 1m2 space’) and the laser automatically works out the best path, adapting to its environment.

A separate project is looking at automated polishing of samples collected from radioactive areas – currently done by humans through gloveboxes. Attendees watched as a robot arm inside a glovebox collected a sample and pushed it against a polishing disc – then moved it across to a microscope to check the finish via a video link.

By using a haptic controller and spring-loaded platform, the robot can achieve human levels of pressure control when performing the polishing. The longer-term goal is to automate much of this process.

Of course, some robot arms will always need human control. So a final demonstration showed how a team from The University of Manchester were translating human hand movement to robot arms using a haptic device. That should make robot teleoperation – where a human operator controls a robot remotely – more natural and efficient.

Want to learn more?

Summing up the importance of the technologies on display, Dr Salvador Pacheco-Gutierrez, Head of RAICo Technology, said:

“Academic research is key to the RAICo programme – solving complex problems that speed deployment of robotics onto decommissioning sites and, in future, into fusion engineering. Our combination of the best academic minds in robotics and AI, with end users on nuclear sites, is what enables us to create deployable technologies that solve real problems.”

In this article, we have provided a very brief overview of the projects on display at the RAICo Academic Showcase. These are at various stages of progress towards their goals, but all have their eyes firmly on real decommissioning challenges – as well as future potential for fusion engineering.

Those wishing to know more about any of these projects can contact [email protected] or sign up to the RAICo newsletter, where we spotlight projects and share news of progress and deployments.