News

How robotics is supporting nuclear decommissioning – an update from the Women in Nuclear Global Conference 2025

18 July 2025

On 15th July, delegates at the Women in Nuclear Global Conference 2025 were treated to a presentation from Bristol University, NDA and Sellafield Ltd, on how robotics is impacting nuclear decommissioning.

The role of robot quadrupeds

Tom Scott, Professor of Materials and Devices at the University of Bristol, began by explaining why quadruped robots were playing such a key role in decommissioning – with the Spot quadruped joining him onstage.

He described a head-to-head test with various robots to see how much contamination they picked up, using a pigment to represent radiation in an artificially radioactive environment. Whilst wheeled robots spread the pigment around, the four small feet of quadrupeds minimised floor contact, leading to an order of magnitude less pickup of contamination.

Such robots also have good maneuverability, ideal for decommissioning environments that may include stairs, rubble, and other unknown unknowns that come with such environments.

In his own presentation, Rav Chunilal, Head of Robotics and AI at Sellafield Ltd, said “Quadrupeds are making a real difference at Sellafield – and Spot is one of the most versatile and robust bits of kit we have, and has been deployed at a multitude of places across the NDA estate.”

The right robot for the right job

But quadrupeds cannot do everything and are certainly not the only game in town. Rav Chunilal went on to discuss how robotics is transforming decommissioning across the Sellafield site.

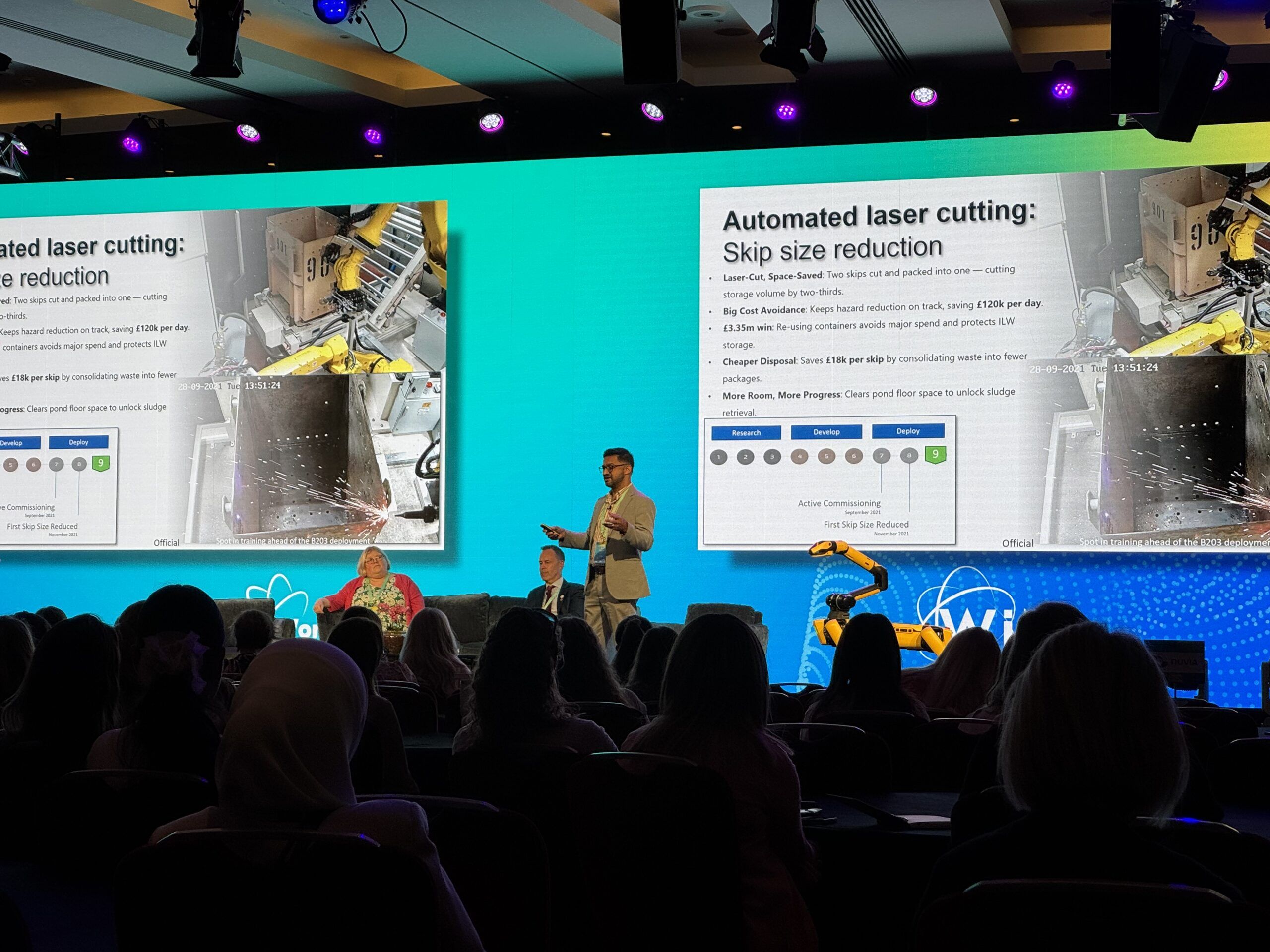

“We’ve deployed UAVs to inspect small crevices where we could never send a human, and we’ve used laser cutting robots to cut up legacy skips so they can be packed up and sent for storage, reducing size by a third.”

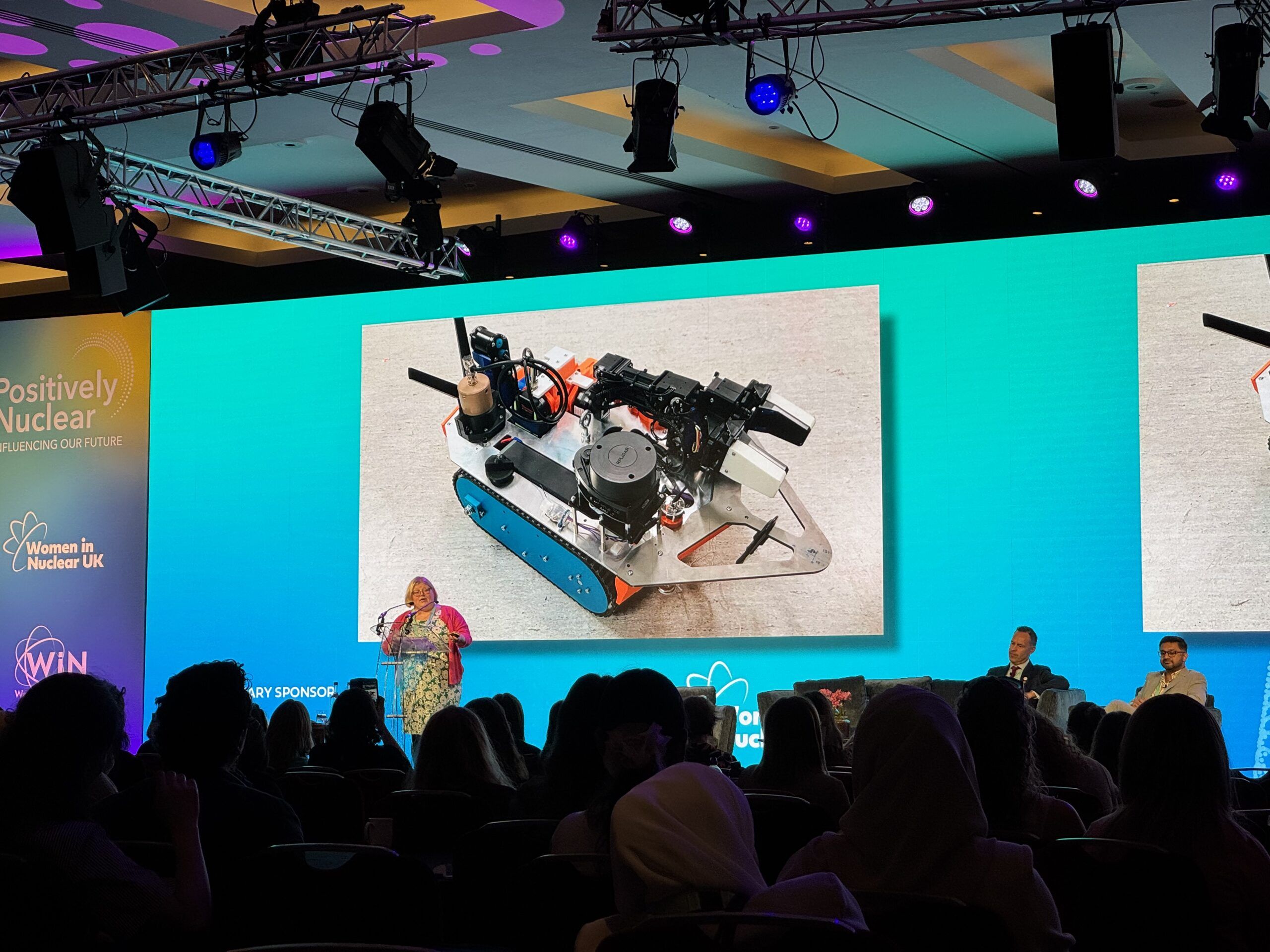

Chunilal praised a RAICo project that deployed the CARMA robot. This “crosses the floor like Roomba vacuum cleaner, but instead of cleaning up dust, it maps the floor for contamination, a laborious and repetitive task. We’ve now proven this in a one-off deployment and we’re ready to do more.”

Safer, faster decommissioning

Tackling why all this mattered, Kate Canning, Head of R&D at NDA, explained why robotics is so critical across the NDA estate.

“We have environments like fuel ponds that are very hard to inspect and unsuitable for humans to enter,” she said. “We want to exploit remote solutions and take humans out of harm’s way.”

“In some areas, like drone surveys, robotics are already business as usual,” Canning said. “We want to repeat that in other areas, from monitoring hazardous environments to hands out of gloveboxes, to remote handling, and size reduction.”

Canning also mentioned NDA’s excitement about the possibilities of simulation for training, allowing people to train offline instead of on real systems. This could allow NDA sites to train a lot more people, a lot faster, with less risk to humans and equipment.

Canning wrapped up her session, saying, “The primary reason is to remove people from harm. But there are lots of other benefits. We can speed up decommissioning, because robots can work 24/7, whereas humans have exposure limits in decommissioning sites. And robots perform some dull repetitive tasks consistently, so we get good comparable data over time.”

“And ultimately, we need to do this. We simply don’t have enough skills and resources for everything we need to do, and that need will grow faster than new skills become available. So, we need robots to fill the resource gap.”

“Collaboration is key to all this,” she concluded. “We can only do this by collaborating with problem holders across NDA and partners like UKAEA, with the supply chain and with academia. Initiatives like RAICo are critical to enabling this.”

“And”, she adds, “if we get all that right, we’ll also support local growth around decommissioning sites and across UK robotics”.