News

An object detection model paves the way for autonomous gloveboxes

09 July 2025

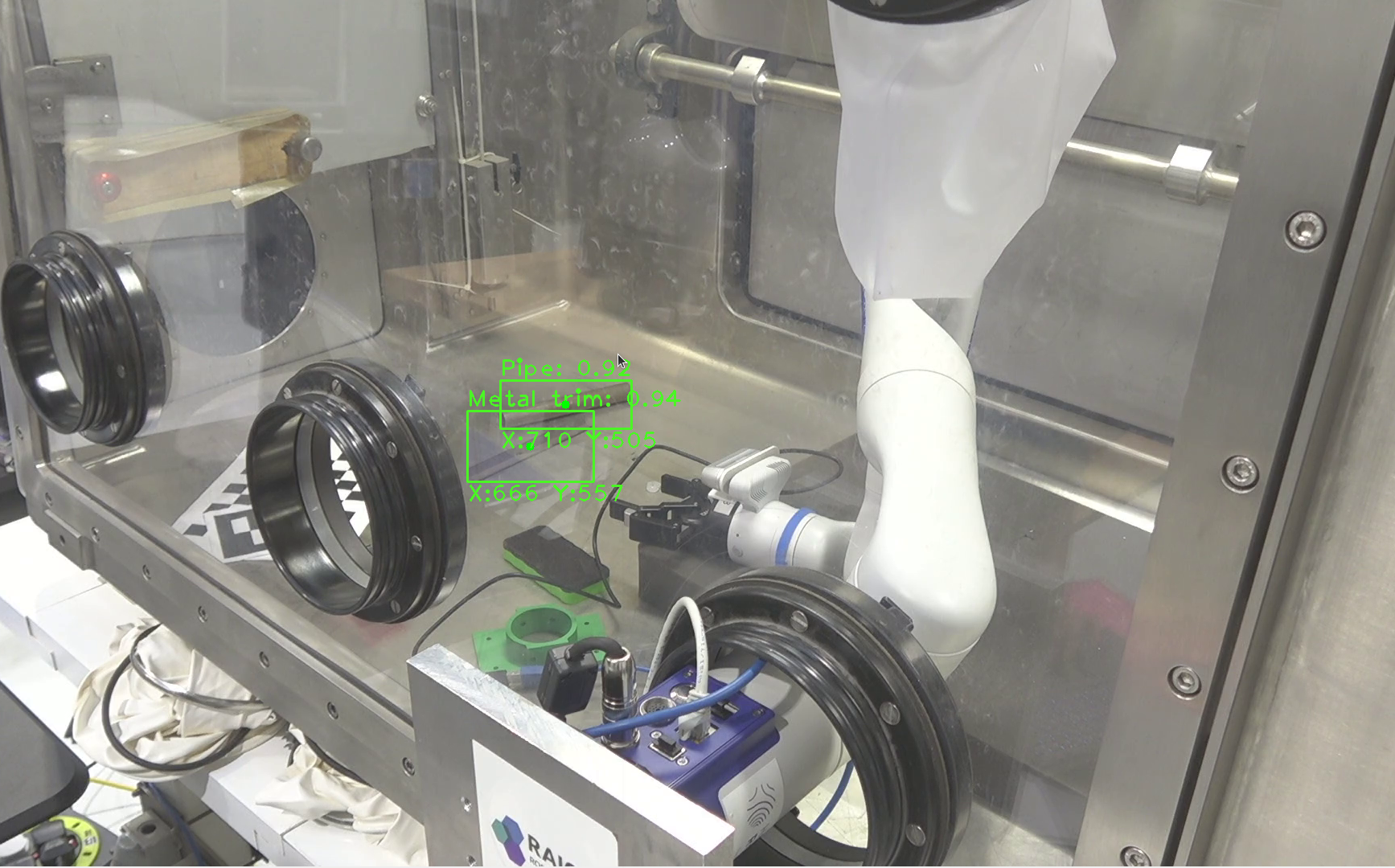

A sharp object detection system, developed at RAICo1, could help prevent damage to robot manipulators in gloveboxes, and pave the way for new teleoperated and autonomous gloveboxes.

Gloveboxes are a staple of decommissioning, allowing operators to manipulate tools and hazardous materials in a contained environment through thick gloves. But thick gloves mean a lack of fine motor control, and a potential risk to operators if torn. Nuclear decommissioning facilities – including those operated by RAICo members – have an interest in “hands out of gloveboxes” through the use of teleoperated arms, robots, and automated systems instead of gloved hands.

A key element of success is enabling robots to detect the objects in gloveboxes. Initially, this may be simply to avoid harm, for example, a system that sees a sharp object and automatically prevents the robot arm (which is wrapped in a protective glove to prevent contamination) from going near it. But, as these systems become more automated and capable, they will need to be able to recognise and manipulate objects with the precision of a human hand.

In a recently completed project, RAICo took the first steps towards creating such an object detection system.

Detecting sharp objects in gloveboxes – a prototype, and a foundation for glovebox automation

To create the glovebox object detection system, RAICo first needed a real use case on which to build their detection model, and prove the concept. In conversations with Sellafield Ltd at RAICo1 (RAICo’s main facility in Whitehaven, Cumbria), a problem in need of a solution was identified: sharp object detection to prevent damage to the robot arms’ protective glove.

Craig West, a Robotics Engineer (UKAEA) engaged with Erwin José López Pulgarín, a Research Associate (University of Manchester), both of whom already work on the RAICo programme at RAICo1. Erwin’s research into defining ‘no-go zones’ to help reduce the cognitive load on glovebox operators had obvious relevance to the sharp object detection prototype.

The team began by developing a realistic representation of a through-gloveport robotic system at RAICo1. Although the setup was technology agnostic, it included mirroring elements of Sellafield’s RrOBO (Risk Reduction of Glovebox Operations) system setup and to ensure reflection of real-world problems. One of these was Sellafield’s use of external cameras to monitor glovebox activity through the window, which meant there was no fixed relationship between the camera and the manipulator’s position. That presented a complex mathematical challenge for the team to solve, to link what the camera was seeing to the manipulator’s trajectory.

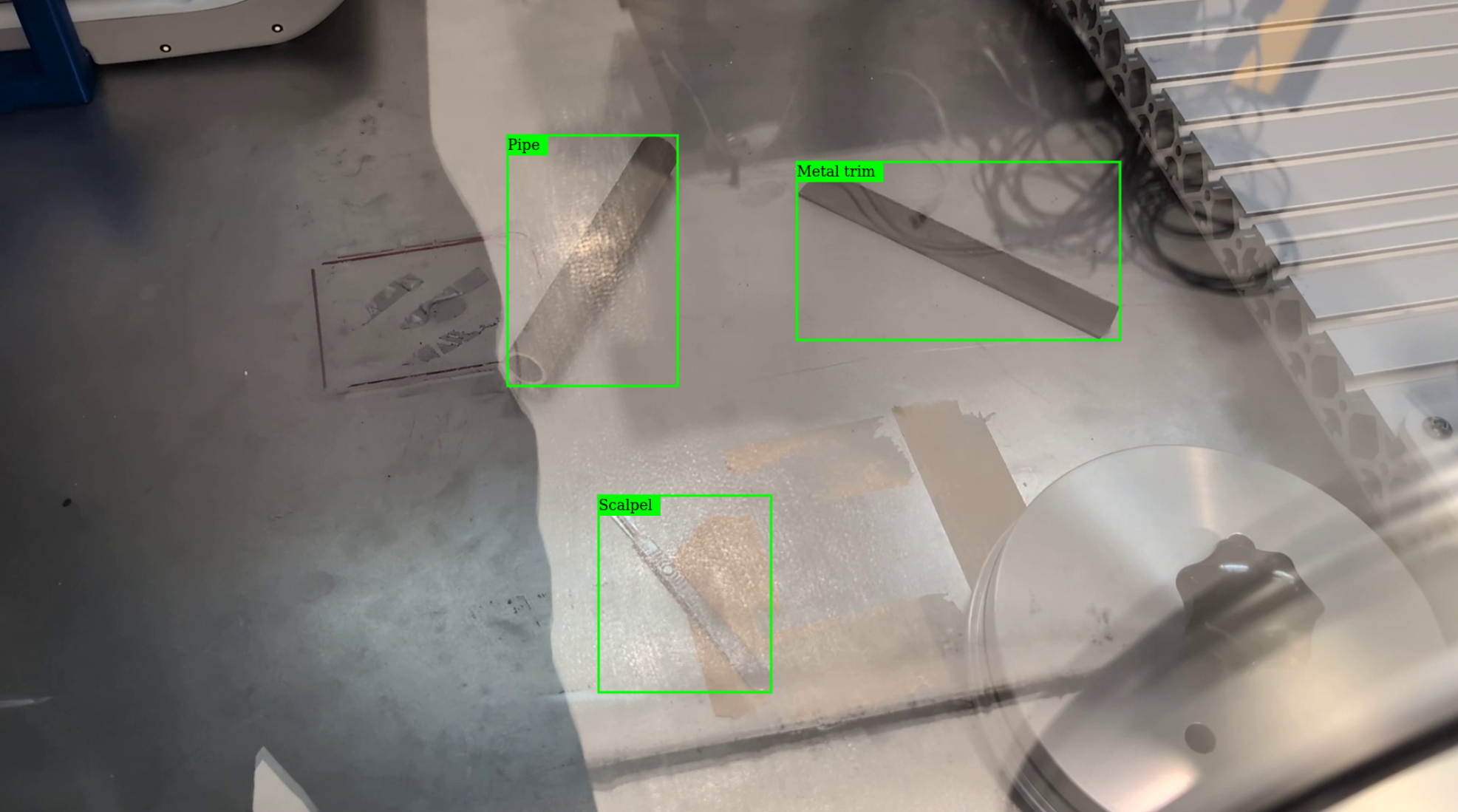

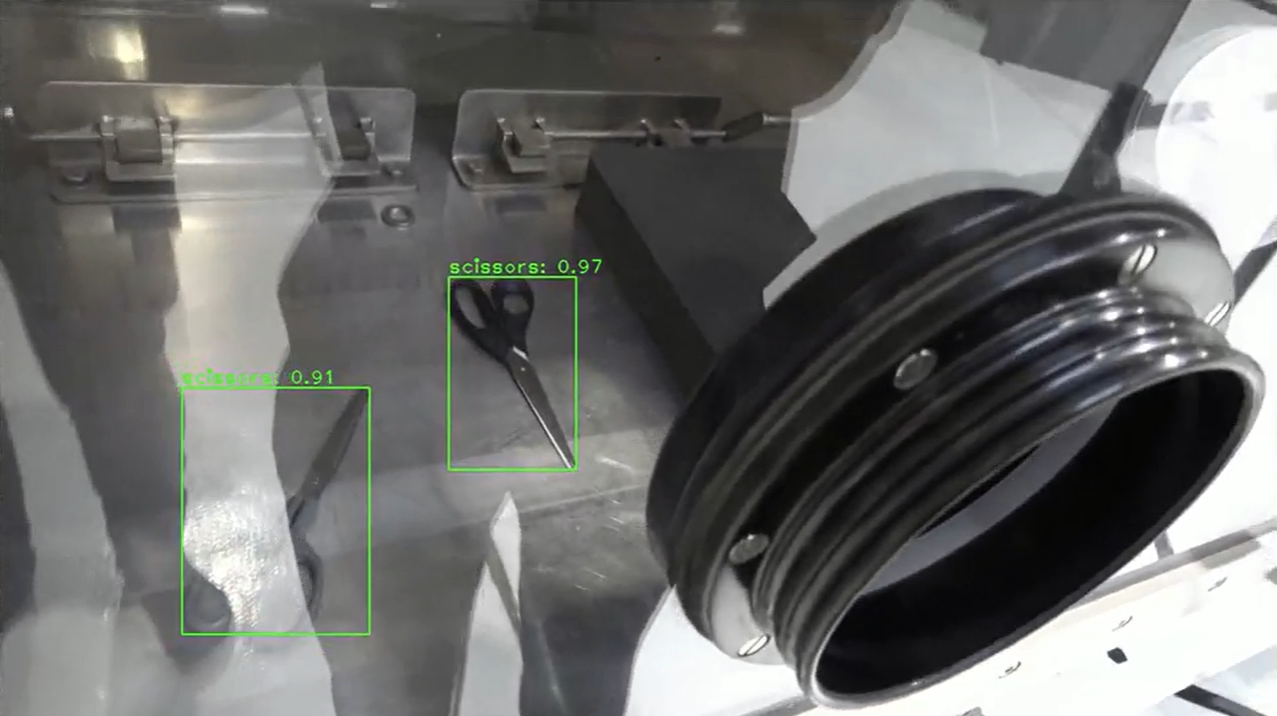

The team then selected an existing object detection algorithm built on a base dataset that included common sharp objects, like scissors and knives. A second dataset was built around a list of commonly encountered sharp industrial objects, provided by Sellafield Ltd. The images for training the algorithm were collected from gloveboxes in RAICo1, in a range of lighting conditions, to make the model as robust as possible.

The outcome

In March 2025, the object detection model was implemented into the manipulator control system in a glovebox mock-up for demonstration in RAICo1.

The demonstration detected sharp objects and created a virtual no-go zone around sharp items to prevent the manipulator from making contact, preventing damage to its glove (the no-go zone can be seen as the red sphere in the image).

This first model was a prototype with a real use case. But its wider purpose was to develop a model for object detection, which sets the foundation for a much broader range of complex uses, and could eventually pave the way for full automation.

Such future use cases include preventing teleoperated or automated robotic equipment from going near anything that might pose a risk, collecting objects for disposal, and grasping and manipulating objects within the glovebox. That could make critical activities, like post operational clean out (POCO) or sample preparation, much safer and efficient. Next steps are currently being explored by the team and end users at RAICo.

Craig West concludes: “This initial project solves a real life challenge that our partners at Sellafield Ltd presented to us, but it also paves the way for a wide range of glovebox autonomy possibilities. We are excited to hear from RAICo partners about their glovebox challenges and work with them to take this work to the next level”.

To contact the team about the project, or explore potential use cases, contact RAICo’s Head of Technology, Salvador Pacheco-Gutierrez, via [email protected]